Robot Welding Services at Metal Workz

Precision, Speed, and Consistency

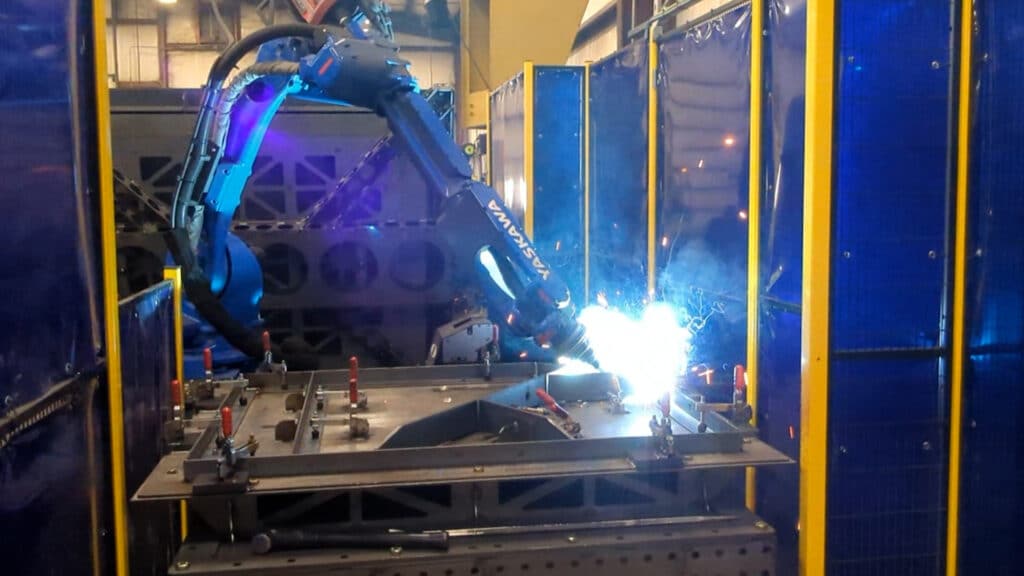

At Metal Workz, our robot welding service combines cutting-edge robotic technology with human expertise. We deliver consistent, high-quality welds on various metal components. This service is particularly advantageous for high-volume production runs. With our robotic systems, we enhance speed while maintaining strict quality control.

What Is Robot Welding?

Definition and Process

Robot welding uses advanced robotic arms equipped with automated controls to perform welding tasks. This method ensures precise and repeatable welds, setting new standards in efficiency and reliability. Each robotic system is programmed to follow exact paths, resulting in uniform results across all products and significantly reducing variability.

Benefits of Robot Welding

Superior Weld Quality and Consistency

Robotic systems provide uniform welds, drastically reducing human error. Each automated weld meets high industry standards, leading to strong and reliable joints for your metal components.

Increased Productivity and Efficiency

Robots operate continuously without the breaks that human workers require. This means production can run 24/7, accelerating timelines and allowing projects to meet deadlines more easily.

Reduced Scrap and Resource Waste

Our robotic welders operate with precise programming, minimizing material waste during production. This not only conserves energy but also leads to cost savings—making your project more economical.

Enhanced Safety

Robot welding limits human involvement in potentially dangerous environments. This reduction in direct human contact with hazardous conditions enhances workplace safety while maintaining productivity.

Cost Savings Over Time

By lowering labor costs and decreasing the likelihood of errors, robotic welding offers long-term savings. Investing in robot welding is an economical choice for businesses looking to improve their bottom line.

Do you have a project?

Wide Range of Industries

Our robot welding services cater to various sectors, including:

- Automotive and Transportation

- Industrial Machinery

- Construction and Infrastructure

- Agricultural Equipment

- Custom Fabrication for Unique Applications

This diverse capability allows us to meet the needs of different projects and industries effectively.

Frequently Asked Questions

What materials can be welded robotically?

We can work with a variety of materials, including steel, stainless steel, and aluminum. If you have special requirements, our team will ensure compatibility with specific materials.

How does robotic welding compare to manual welding?

Robotic welding outperforms manual methods in speed and consistency, making it ideal for repetitive tasks or high-volume production. Manual welding is often better suited for unique or small-batch projects that require flexibility and adaptability.

Can robot welding help with urgent deadlines?

Yes, robotic welding is ideal for meeting tight deadlines. Continuous operation and minimal downtime allow us to deliver projects faster, without sacrificing quality.

Let’s Build Your Next Project

Experience the advantages of robot welding with Metal Workz. Our blend of innovation and precision can bring your projects to life. Contact us today for a quote or personalized consultation. Let us help you achieve your welding goals with efficiency and excellence.

Robot Welding in Kentucky

Metal Workz LLC offers expert metal fabrication services in Kentucky, specializing in high-quality robot welding. Our advanced technology ensures precision and efficiency in each weld, providing strong and reliable results for your projects. Whether you need custom parts for manufacturing or repairs for existing equipment, we tailor our robot welding services to meet your specific needs. Partner with us to elevate your metal fabrication experience and achieve consistent, durable outcomes.

FAQs - Robotic Welding

What are the key benefits of utilizing robot welding in metal fabrication?

- Robot welding offers superior weld quality and consistency, increased productivity and efficiency, reduced scrap and resource waste, enhanced safety, and cost savings over time.

Which industries can benefit from robot welding services offered by Metal Workz?

- Metal Workz serves a wide range of industries, including automotive and transportation, industrial machinery, construction and infrastructure, agricultural equipment, and custom fabrication applications.

How does robot welding ensure enhanced safety in the workplace?

- Robot welding limits human involvement in potentially dangerous environments, reducing direct human contact with hazardous conditions and enhancing workplace safety.

What types of materials can be welded using robotic systems at Metal Workz?

- The robotic systems at Metal Workz can work with various materials, including steel, stainless steel, and aluminum. Compatibility with specific materials can be ensured if there are special requirements.

Is robot welding suitable for projects with urgent deadlines, and how does it compare to manual welding in such cases?

- Yes, robot welding is ideal for projects with urgent deadlines due to its ability to operate continuously with minimal downtime. It outperforms manual welding in speed and consistency, making it suitable for high-volume production tasks.

Contact Us Today

Are you ready to bring your designs to life? Trust Metal Workz for precision bending and forming services that deliver outstanding results. Contact us today to discuss your project and get started!