Deburring Services in Kentucky

Our deburring service in Kentucky removes imperfections left after laser cutting, ensuring your sheet metal parts are ready for immediate use. Addressing these imperfections is crucial for the overall quality of your components.

What Is Deburring?

Deburring is the process of removing raised edges or small fragments called burrs from metal parts. Burrs can form during machining activities such as laser cutting, punching, or stamping. If left unaddressed, these burrs can create several issues, impacting safety, assembly, and functionality.

Why Is Deburring Essential?

Safety

Burrs can pose a risk of injury during handling and assembly. Removing these sharp edges reduces the chances of cuts or other accidents, making your parts safer to work with.

Quality & Appearance

Deburring enhances the visual appeal of your components. Clean and smooth edges contribute to a professional finish, increasing the value of your product.

Functionality

Deburred components fit together more accurately. This precision ensures optimal performance in assemblies, minimizing wear and malfunction.

Extended Equipment Life

Parts free of burrs decrease the risk of damage to tools and machinery. This extends the lifespan of your equipment, reducing maintenance costs and downtime.

Our Deburring Methods

We use a variety of methods to meet your deburring needs. Here are some of the techniques we employ:

Manual Deburring

Our skilled technicians use hand tools for precise burr removal. This method is ideal for small or intricate parts.

Mechanical Deburring

We utilize advanced machinery like abrasive belt sanders and grinders. This process efficiently handles larger or higher-volume parts while keeping quality consistent.

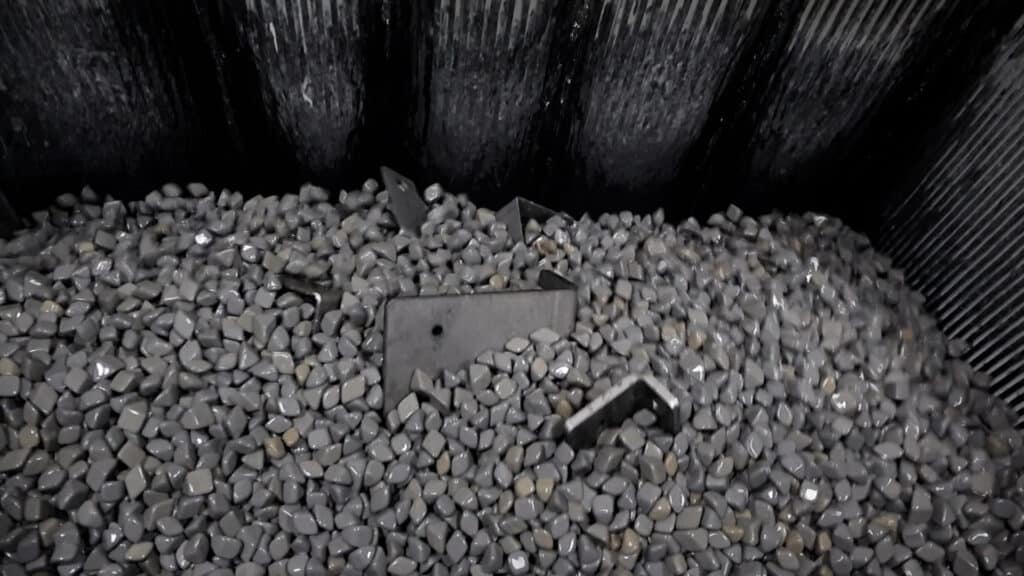

Vibratory & Tumbling Deburring

This technique works well for batches of smaller parts. It uses media in vibrating or rotating chambers to smooth edges gently.

Additional Techniques

For unique requirements, we offer specialized deburring methods that include cryogenic, electrochemical, or thermal processes.

Materials We Deburr

We can handle the following materials with our deburring services:

- Steel

- Aluminum

- Stainless Steel

- Brass

- Copper

Industries Served

Our deburring services cater to various industries, including:

- Manufacturing

- Electronics

- Automotive

- Aerospace

- Industrial Equipment

The Metal Workz Difference

Expertise & Care

Our experienced team specializes in sheet metal fabrication and finishing, ensuring high-quality results.

Customized Solutions

We adjust our deburring methods to fit your specific requirements, whether for intricate parts or large-scale production.

Quality Assurance

Each part undergoes thorough inspection to meet stringent safety and performance standards.

The Metal Workz Difference

Expertise & Care

Our experienced team specializes in sheet metal fabrication and finishing, ensuring high-quality results.

Customized Solutions

We adjust our deburring methods to fit your specific requirements, whether for intricate parts or large-scale production.

Quality Assurance

Each part undergoes thorough inspection to meet stringent safety and performance standards.

Why Choose Metal Workz?

Choosing Metal Workz means selecting quality, efficiency, and expertise. Our commitment to superior craftsmanship and customer satisfaction sets us apart in the metal fabrication industry.

Deburring in Kentucky

Metal Workz LLC is your go-to metal fabrication service in Kentucky. We specialize in high-quality deburring processes that remove imperfections from your sheet metal parts. Our laser cut deburring technique eliminates scratches and burrs efficiently, ensuring a smooth finish that meets your standards. Whether you need a small batch or a large production run, our team is ready to enhance the quality of your metal products. Trust Metal Workz LLC for precision deburring that improves both appearance and performance.

FAQs - Deburring Services

1. What is deburring and why is it important?

Deburring is the process of removing raised edges or small fragments, known as burrs, from metal parts. It’s crucial for ensuring safety, enhancing the appearance, maintaining functionality, and extending the lifespan of equipment by preventing damage and wear.

2. What techniques does Metal Workz use for deburring?

Metal Workz employs several deburring methods, including manual deburring, mechanical deburring with abrasive tools, and vibratory/tumbling deburring. Additionally, they offer specialized techniques like cryogenic, electrochemical, or thermal deburring for unique requirements.

3. Which materials can be deburred by Metal Workz?

Metal Workz provides deburring services for a variety of materials including steel, aluminum, stainless steel, brass, and copper.

4. What industries benefit from Metal Workz’s deburring services?

Metal Workz serves multiple industries with its deburring services, including manufacturing, electronics, automotive, aerospace, and industrial equipment sectors.

5. How does Metal Workz ensure the quality of their deburring services?

The company employs experienced technicians and offers customized solutions to fit specific client needs. Each part undergoes a thorough inspection to meet the industry’s safety and performance standards, ensuring high-quality results.

Contact Us Today

Contact Metal Workz today to learn more about our deburring services. Reach us via phone, email, or use our contact form. Enhance the quality and safety of your sheet metal parts with our expert deburring services!