Tumbling Service at Metal Workz

Tumbling is a crucial metal finishing process. It enhances the quality and appearance of metal parts by removing burrs, deburring them, and polishing surfaces. This service is vital in various industries due to its efficiency and cost-effectiveness. Tumbling improves durability and aesthetics, making it a preferred choice for many manufacturers.

How Tumbling Works

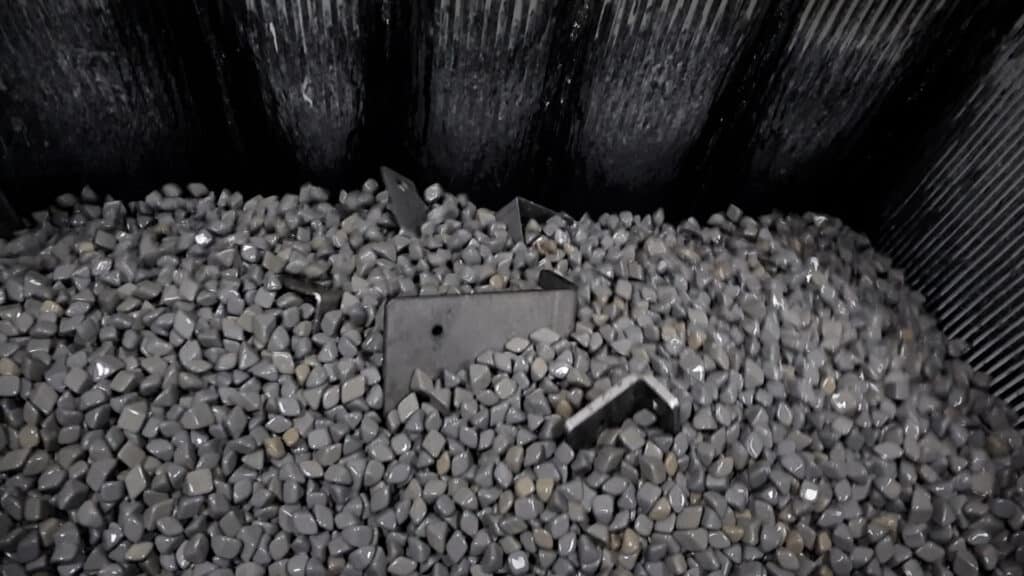

Tumbling involves placing metal parts in a rotating barrel with abrasive media. This media can be ceramics, steel shot, or synthetic materials. As the barrel rotates, the media rubs against the parts, smoothing and polishing them.

The Countersinking Process

Our countersinking process guarantees precision and efficiency through advanced techniques. Here’s how we achieve high-quality results:

Pilot Hole Drilling

We start by drilling a pilot hole. This initial step guides the countersink tool and ensures accurate alignment for a flawless finish.

Precision Countersinking

Next, we swiftly move to precision countersinking. Using specialized CNC technology, we create a conical depression at the hole’s opening. We customize the tool’s angle to match the screw head design, commonly set at 82° or 90°.

Deburring and Finishing

Finally, we add finishing touches by deburring. This step removes any sharp edges or imperfections, leaving a smooth surface ideal for assembly.

Benefits of Tumbling

Efficiency

Tumbling can process large batches of parts with minimal supervision. This automation makes it an economical option for mass production.

Precision and Uniformity

Tumbling provides a consistent finish across all parts. This uniformity ensures that each piece meets quality standards.

Cost-Effectiveness

Compared to manual polishing, tumbling saves time and labor. It is a more efficient method, particularly for large quantities.

Types of Tumbling

There are two primary types of tumbling:

Barrel Tumbling

Barrel tumbling uses a rotating drum where parts tumble with abrasive media. This method effectively smooths surfaces.

Vibratory Tumbling

Vibratory tumbling employs a vibrating machine to agitate parts and media. This results in an evenly finished product, perfect for delicate items and intricate designs.

Types of Tumbling

There are two primary types of tumbling:

Barrel Tumbling

Barrel tumbling uses a rotating drum where parts tumble with abrasive media. This method effectively smooths surfaces.

Vibratory Tumbling

Vibratory tumbling employs a vibrating machine to agitate parts and media. This results in an evenly finished product, perfect for delicate items and intricate designs.

Applications of Tumbling

Tumbling finds applications in numerous industries:

- Metalworking: For deburring and polishing metal parts, enhancing durability and appearance.

- Jewelry Manufacturing: Used for smoothing and polishing metal surfaces, achieving a high-gloss finish.

Tumbling Services at Metal Workz

Metal Workz offers a comprehensive tumbling service to meet your needs:

- Deburring and Polishing: We remove unwanted edges and burrs, creating smooth, polished surfaces.

- Surface Enhancement: We reduce blemishes and handling scratches, improving overall product quality.

- Customized Finishing: Our team tailors the tumbling process for specific materials and desired finishes.

Why Choose Metal Workz for Tumbling?

Several reasons make Metal Workz the best choice for your tumbling needs:

- Expertise: Our team has extensive experience in metal finishing techniques.

- State-of-the-Art Equipment: We utilize advanced tumbling machinery to handle various part sizes.

- Quality Assurance: We ensure consistent and high-quality finishes for all products.

Looking for efficient tumbling services? Contact Metal Workz today for more information or to schedule your tumbling service.

FAQs - Tumbling

What is the primary purpose of tumbling in metal finishing?

- Tumbling is used to remove burrs and polish surfaces of metal parts, enhancing their quality and appearance. This process increases durability and aesthetics, making it an efficient and cost-effective solution for manufacturers.

Can the tumbling process be customized for different materials?

- Yes, the tumbling process can be customized for various materials such as steel, aluminum, and alloys. This customization helps achieve the desired surface finish according to specific requirements.

What are the main types of tumbling processes?

- There are two main types of tumbling: barrel tumbling, which uses a rotating drum, and vibratory tumbling, which employs a vibrating machine to agitate parts and media. Each method is suited for different types of parts and finishes.

What industries commonly use tumbling services?

- Tumbling is widely used in industries like metalworking for deburring and polishing metal components and in jewelry manufacturing for creating smooth, high-gloss finishes on metal surfaces.

Why should one choose Metal Workz for tumbling services?

- Metal Workz offers expertise in metal finishing, state-of-the-art equipment, and a commitment to quality assurance. Their services include deburring, polishing, surface enhancement, and customizable finishing processes to meet specific needs.

Contact Us Today

Are you ready to bring your designs to life? Trust Metal Workz for precision bending and forming services that deliver outstanding results. Contact us today to discuss your project and get started!